Spring pump start-ups can be pretty simple—especially if the pump was winterized properly! When you run into issues, Munro’s irrigation pump troubleshooting guide has step-by-step instructions to help you solve most common problems. And this year, it’s even available in Spanish.

Spring pump start-ups can be pretty simple—especially if the pump was winterized properly! When you run into issues, Munro’s irrigation pump troubleshooting guide has step-by-step instructions to help you solve most common problems. And this year, it’s even available in Spanish.

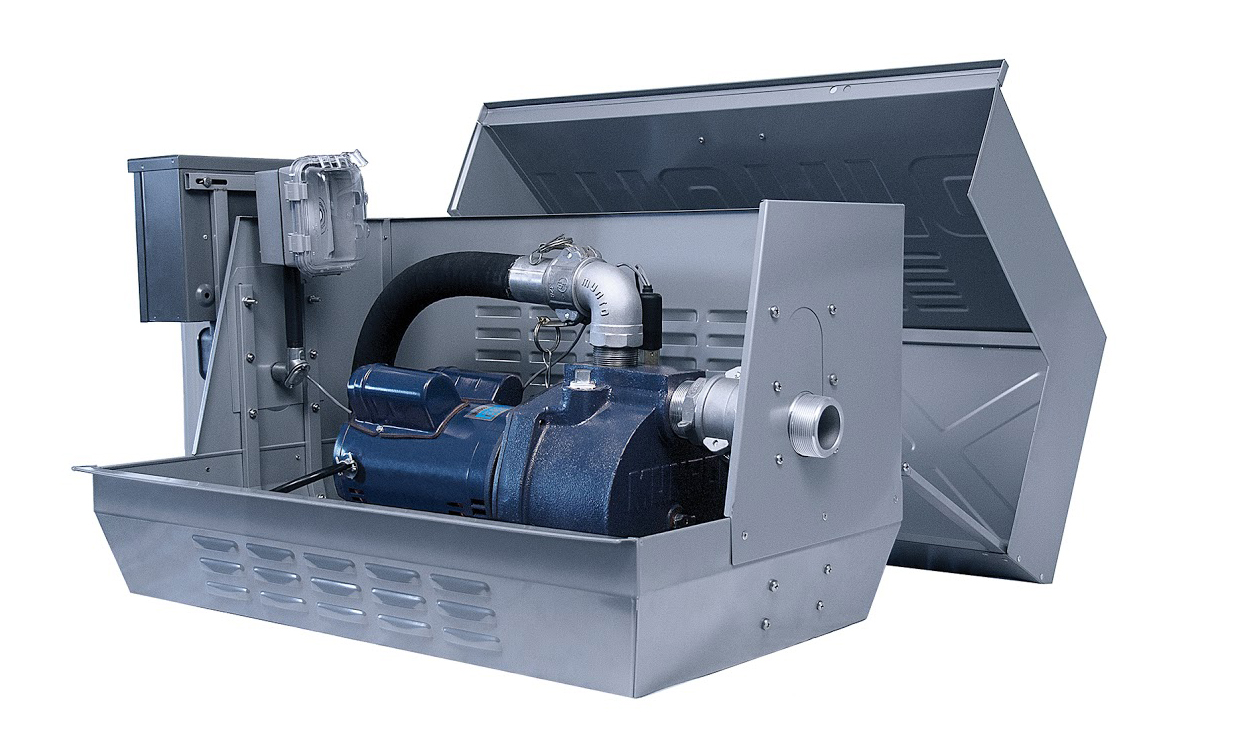

Follow these steps for a straightforward pump start-up.

- Inspect gaskets and O-rings. Union joint O-rings and cam-fitting gaskets should be inspected or replaced every year or two. O-rings and gaskets can harden over time and become brittle, causing air leaks.

- Check valves and filtration. Check your foot valve to be sure it is clear and operating properly. Check any other valves or filtration.

- Check connections. Reconnect any piping or fittings that were disconnected for winterization. Make sure that all suction and discharge connections are tight, and that your suction line does not have any bellies in it that can trap air.

- Prime it. Close the drain valves and fill the priming port with water.

- Get control. Turn on the irrigation controller. Is the controller programmed properly to turn on the pump when needed? Remember, not all systems need the pump on every zone.

- Power it up. Check the breaker and any plugs to make sure that the pump has power.

Troubleshooting Tips

If things don’t run smoothly, these troubleshooting tips may help you identify the issue and determine whether you need to take the pump to a service center.

- Take a good look around. Review your whole system. Has anything changed? Do you have more or fewer sprinkler heads or zones? Have you had any vermin problems or is there a new pet?

- Motor issues? Check volts. While the motor is running, use a voltmeter to determine if line voltage getting to the motor is the same as indicated leaving the breaker box.

- Suction issues. 80 percent of all pump issues are on the suction side. Check your piping, filtration and water source for possible changes or issues.

- Air leaks. Think you might have an air leak? Check for air leaks using plastic wrap. Wrap plastic wrap tightly around a potential air leak path (union joint or cam fitting), and turn pump on. If an air leak exists, the plastic wrap will tighten to the area.

- Debris in the switch. Think you might have an issue with the centrifugal switch? Debris can get caught in the centrifugal switch inside the motor. A soft hammer or 2x4 board can be used to firmly tap the butt of the motor. After three or four taps, try to engage the motor. If necessary, repeat.

- Bump it. To avoid an unnecessary trip, try jostling any debris inside the pump free before bringing your pump to a repairman.

Questions? Problems? Think you may need a new pump? Save yourself some time, by calling the Ewing Pump Hotline at 1-844-PUMP-PRO, or email for help with your pump questions!

Questions? Problems? Think you may need a new pump? Save yourself some time, by calling the Ewing Pump Hotline at 1-844-PUMP-PRO, or email for help with your pump questions!